Tel:0574-59128998

Fax:0574-59128930

Mail:sales@nbyiduan.com

Add:Dalin village, Huangbiao Town, Xiangshan County, Ningbo, China

Web:www.nbyiduan.com

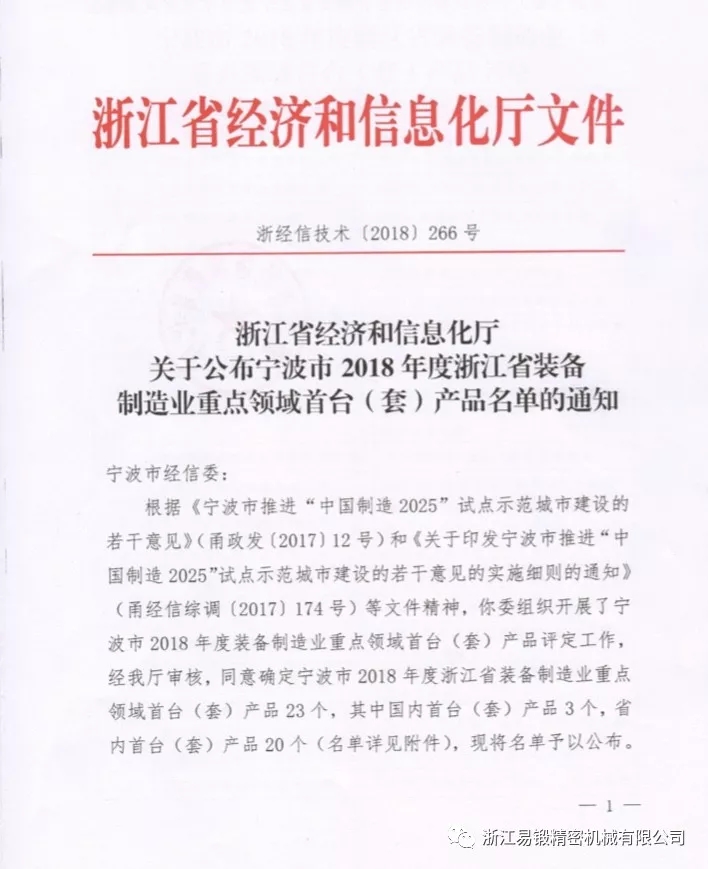

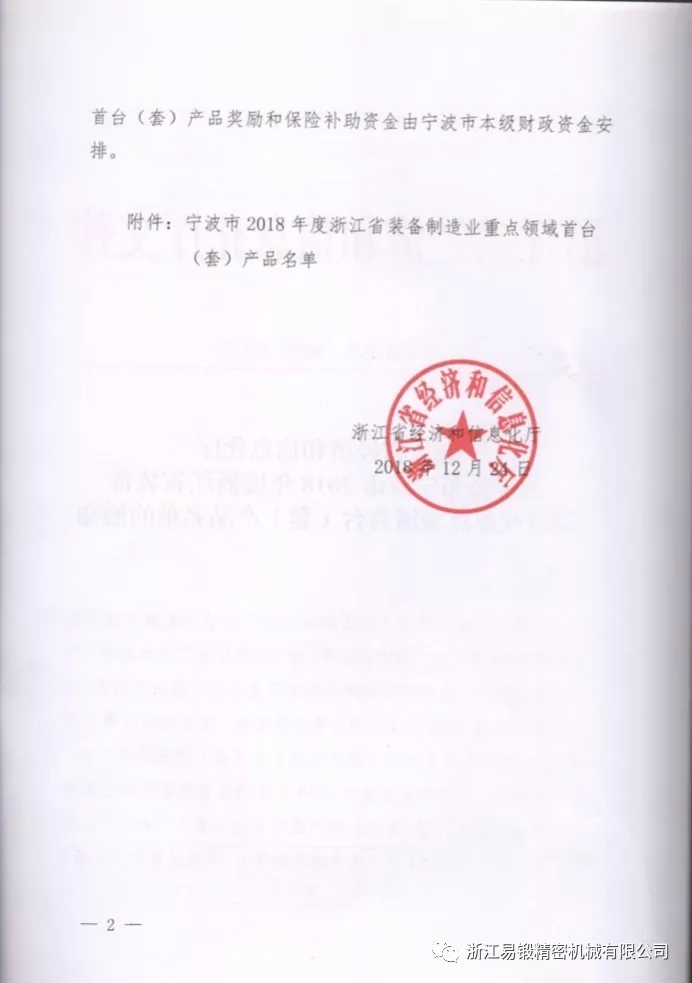

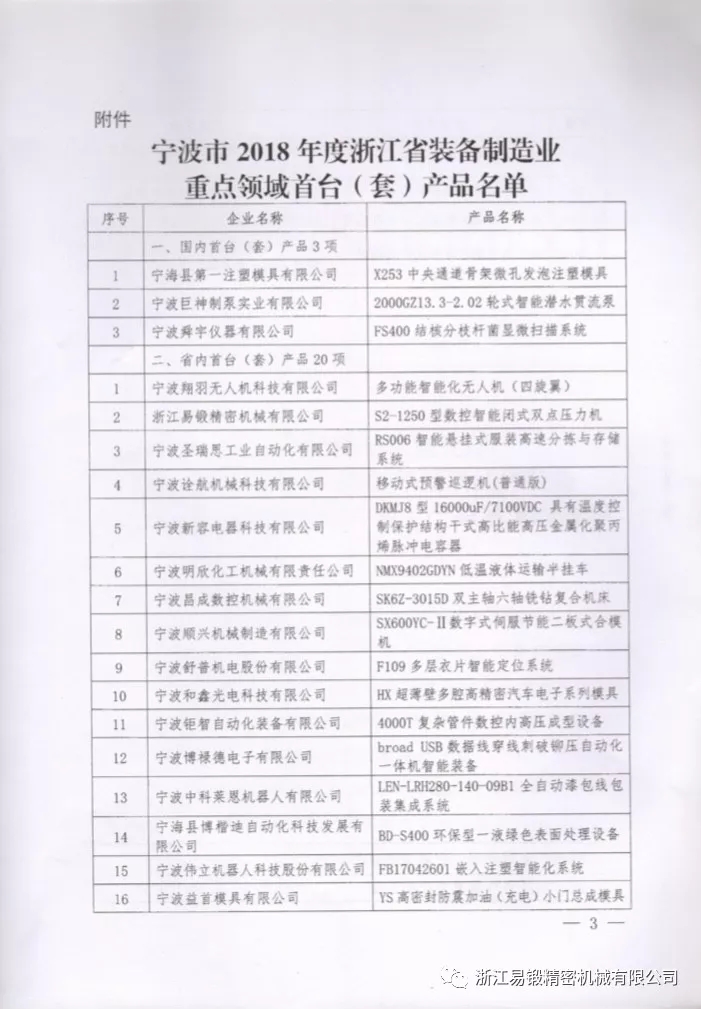

2018年12月24日,浙江省经济和信息化厅公布了“宁波市2018年度浙江省装备制造业重点领域首台(套)产品”名单(浙经信技术【2018】266号),浙江易锻精密机械有限公司生产的“S2-1250型数控智能闭式双点压力机”荣获宁波市2018年度浙江省装备制造业重点领域首台(套)产品。

Product introduction of S2-1250 intelligent CNC closed double point press

The S2-1250 CNC intelligent press integrates new technologies such as machinery, electronics, computers, hydraulics, pneumatics, and testing. It is a key equipment for stamping companies to realize unmanned smart factories and "Made in China 2025". It is widely used in energy transportation. (Automotive, etc.), aerospace (aircraft, etc.), household appliances, construction machinery and other industries.

1. Product features

1. The product adopts a double movable workbench, which can realize rapid mold replacement during work without stopping production; the balance cylinder and air cushion air pressure (including stroke) can be automatically adjusted according to mold parameters, supplemented by a quick mold change device, Meet the requirements of one-key mold adjustment. Equipped with a three-dimensional manipulator, it can achieve the stamping requirements of one die with two parts or one die with four parts, which can continuously reach 12-18 times per minute, with high efficiency (can be increased by 4-8 times) and stable quality.

2. The press has a top dead center slide block fixed lock, front and rear safety doors can be automatically raised and lowered, dual-circuit electrical design, perfect protection, low noise, fully comply with EU CE standards, and accuracy meets the internationally accepted JIS level one standard, which can be implemented in the EU Export.

3. The press uses the Internet of Things technology and 4G card to remotely monitor, debug, and view data. It can seamlessly connect with the factory ERP and MES systems to realize intelligent data analysis and management.

2. Technical advantages

1. The main drive adopts a split clutch brake, and the brake is equipped with an air cooling system for the in and out axial motor. Since the clutch is the heart of the press, the use of this structure can solve the problem of dry clutch brake heating, non-wear friction materials and frequent replacement, unstable machine performance, and long-term maintenance-free machine tools. The main drive of the traditional closed press uses a combined clutch brake (wet or dry) or a split dry clutch brake. The friction plate (block) needs to be replaced regularly, the frequency of machine sheets is low, and the performance stability is poor.

2. Adopt the integrated method of lubrication and hydraulic double pumps. The lubrication system and the hydraulic clamping and lifting system of the mobile worktable adopt the integrated design of double pumps. The overall appearance is beautiful, the installation space is small, the oil consumption is small, the oil tank volume can be reduced, and the design is centralized. There are fewer problems and easy maintenance. Stable and reliable performance, motor saving, energy saving, and small foundation space. Traditional presses are all separated and have two systems, occupying a large space, not centralized, inconvenient to find problems, high failure rate, and foundation space needs to be increased.

3. The connecting rod bearing is lubricated by progressive oil pool. The connecting rod bearing bush is lubricated by a progressive oil pool. The progressive lubrication point is placed on the upper casing and is not rigidly connected to the connecting rod. There is an oil pool on the upper part of the connecting rod. Because the connecting rod only swings during movement, this The upper oil drips directly into the oil pool without clogging and sufficient lubrication. The traditional press adopts rigid connection, which is easy to break at the joint, causing lubrication failure and burning of the connecting rod copper bush.

Three, intelligent CNC

1. Air cushion air pressure and balance cylinder air pressure are automatically adjusted in closed loop, air cushion stroke is adjustable, with top dead center buffer, main motor inverter MODBUS communication control.

2. Front and rear safety doors with automatic lifting.

3. Equipped with Internet of Things technology and 4G card, remote monitoring, debugging and data viewing can be carried out.

4. It can store 500 sets of mold data, and realize one-key adjustment of some parameters of the press according to mold parameters.

Expertise in researching and developing precision and high speed punching press machine!

pursue quality with dedicated service