1、 Precision selection

As the saying goes, "if you don't have a diamond, don't do porcelain work." if you want to do a good job, you must first sharpen your tools.

Market competition is becoming more and more fierce. If an enterprise wants to develop continuously and improve its competitiveness, we should not only save costs, but also improve product quality. To produce a qualified product, maybe the general punch can guarantee it, but if all the commodities are good, we need to buy a punch with high precision.

The key points of punch precision are: 1. Parallelism; 2. Perpendicularity; 3. Total gap.

In order to ensure that the dynamic dead center will appear deviation within the cause, to promote the production of every commodity is up to standard, mold accessories will not be damaged.

High precision punch not only can produce good products, but also has less damage to the mold, not only saves the mold maintenance time, but also saves the maintenance cost.

2、 Speed selection

At present, there are two kinds of speeds for Taiwan punch press and Chinese punch press, which are called high speed. One is the highest speed of 400 times / min, and the other is 1000 times / min.

If the speed of your commodity mould is 300 times / min or higher, you should choose 1000 times / min punch.

Since the equipment can not be used to the limit, and generally there is no forced lubrication system for presses within 400 times / min, only grease lubrication is used in a part of the knuckle.

In addition, the structure of the punching needle adopts the slider type, so the accuracy can not be guaranteed. In the long-term work, the wear is rapid, the precision is reduced, the mold is easy to be damaged, and the equipment and mold maintenance rate is high, and delay time, harm the delivery time.

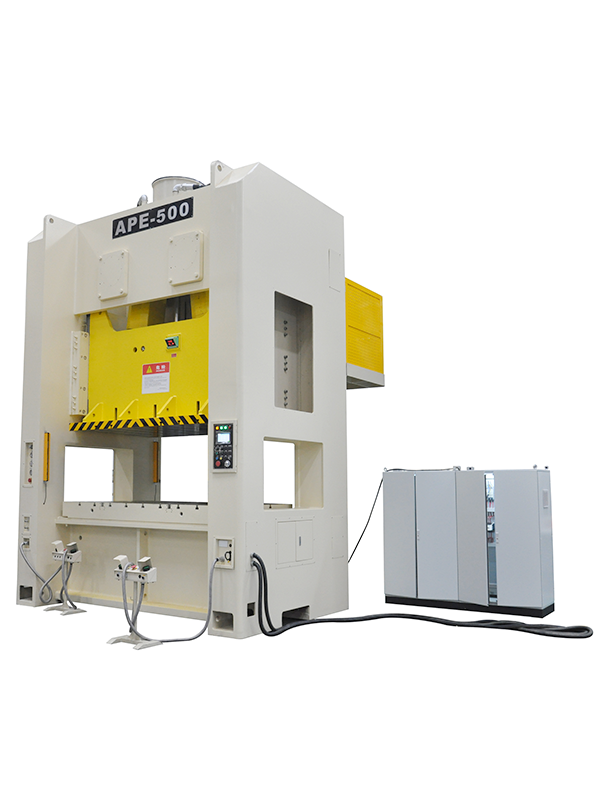

3、 Appearance structure

Good structure can ensure the accuracy of the equipment.

The foot base of punch is the basic of the machine, and the shell is the guarantee of the accuracy of the machine.

4、 Scale and strength of manufacturers

The scale and strength of the manufacturer should also be considered when purchasing equipment.

As some parts of punch press are forged by unique forging, once the manufacturer stops production, it will cause great confusion for the maintenance afterwards.

5、 After sales service

After sales service is also the key to consider. If the equipment is used for a long time, it is inevitable that there will be failures

1. Punch manufacturer reply and maintenance speed.

2. Maintenance costs.

3. Choose the maintenance level of the manufacturer.

6、 Industry recognition of punch quality