Zhejiang Yidan's work results in the past three years

Zhejiang Yi Duan was established in September 2011. It has experienced four stages of start-up, growth, transformation and development. The company has grown from small to large, and from weak to strong. Especially since 2016, the company has insisted on promoting transformation through technological innovation, promoting development through innovation, and increasing efficiency through management, and has entered the track of sound development.

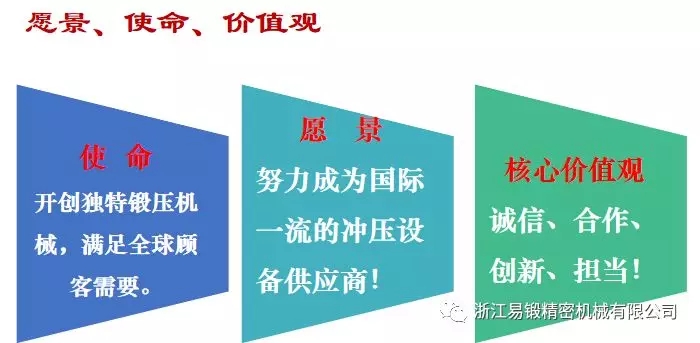

1. Senior leaders practice their own actions and lead the company to develop rapidly. With the vision of "strive to become a world-class stamping equipment supplier", we will strive to fulfill the corporate mission of "creating unique forging machinery to meet the needs of global customers" and insist that "customers are God, reputation is wealth, teamwork, and dedication." Core values. Under the leadership of Chairman Wang Da, since the establishment of the company’s predecessor Ningbo Hailun Processing Factory in 1993, Chairman Wang Da has led employees to experience 25 years of hard work, hard work, and unremitting exploration, from the beginning of component processing to the later From the four stages of start-up, growth, transformation, and development, the company has grown from small to large, and from weak to strong. Especially since 2016, the company has adhered to the strategy of innovation and development and technology-strengthening enterprise, achieved independent research and development, technology leadership, production in compliance with standards, standardized management, and entered the track of sound development. In 2017, the company's sales revenue reached 164.34 million yuan, an increase of nearly 300% over 2016. It has won high recognition from all levels of government, all walks of life, new and old customers. And successively won the national high-tech enterprise, Zhejiang high-growth high-tech small and medium-sized enterprise, Xiangshan county power enterprise, science and technology star and other honorary credit titles.

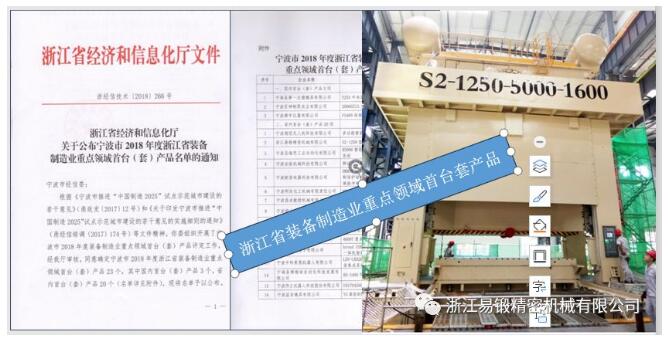

2. Increase investment in technological transformation and promote product upgrades. Zhejiang Easy Forging began to invest in two phases of technological transformation projects in 2015, with a total investment of nearly 100 million yuan, introduced large-scale CNC forming and stamping equipment production lines, and put it into production in January 2018. The maximum punching force of the product reached 1,600 tons, which is a large-scale stamping Compared with ordinary domestic stamping equipment, the advantages of the company’s products are reflected in the automatic adjustment and automatic display of air pressure, pneumatics, stamping speed, air cushion, etc. during the production process, which is convenient for maneuvering management during the production process. At the same time, the equipment is equipped with a rapid mold making device and a mold making trolley, which realizes automatic mold replacement. With the addition of robots and robots, the functions of automatic feeding, handling and multi-machine connection are realized. At present, it has produced TE2-1600, TE2-1250, STD-1250, STS1000, S2-800 and other large and medium-sized CNC press products, which have won high attention and praise from customers and peers.

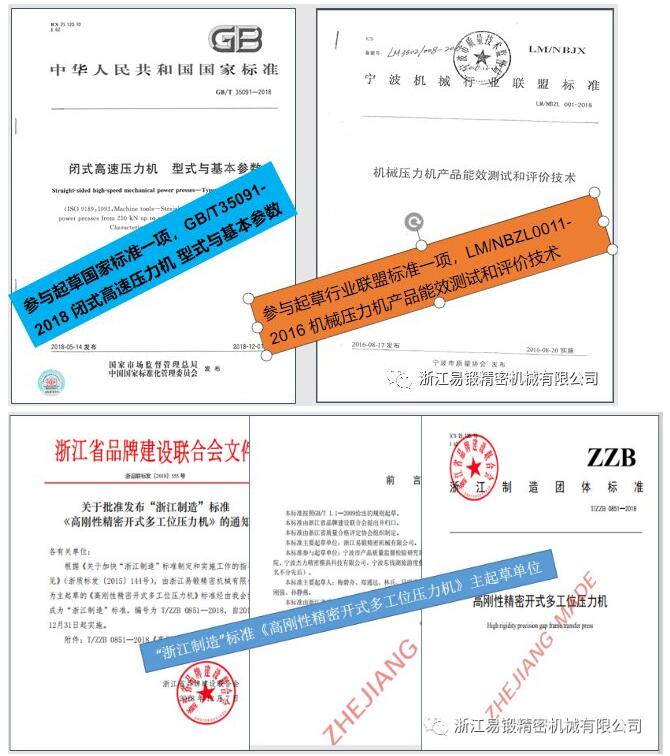

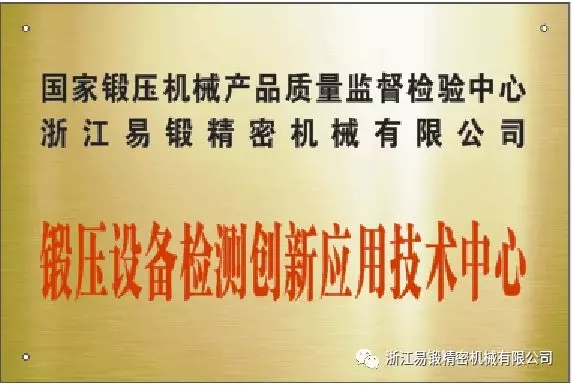

3. Persist in technology-driven and remarkable innovation results. Establish the concept of "strengthening the enterprise with science and technology", with the goal of "reducing costs, improving quality, promoting safety, and creating results", and insist on technological innovation and technological transformation. Established expert workstations, carried out industry-university-research cooperation with Zhejiang University, Zhejiang Wanli College, etc., and established a forging equipment testing and innovation application technology center with the National Forging Machinery Product Quality Supervision and Inspection Center, and successfully applied for municipal technology centers and post-doctorate workstations, combined with presses The intelligent and key intelligent CNC press project has carried out research on new technologies and new processes, and has formed an intelligent CNC press technology research and development team of nearly 22 people, and adopts three-dimensional design, finite element analysis and three-dimensional PDM drawing management. The "S2-1250 CNC Intelligent Closed Double Point Press" completed in 2018 has passed the expert appraisal organized by the Ningbo Municipal Commission of Economy and Information Technology. The main technical performance of the product has reached the domestic leading level and won the key field of equipment manufacturing in the province in 2018. The first set of products. Now has 2 invention patents, 23 utility model patents, accepted 7 invention patents, 4 utility model patents, participated in one national standard (GB/T35091-2018), and one local industry standard (LM/NBZL 001- 2016), Zhejiang made two project standards (the fourth batch of 2018-high rigidity and precision open multi-station presses, the fifth batch of 2018-high rigidity semi-closed precision single and double point presses.), the company is now Is applying for five Zhejiang manufacturing industry standards (1, high-rigidity and precision four-point press, 2, high-rigidity and precision closed multi-station press 3, high-rigidity and precision integrated frame closed single and double-point press, 4, high Rigid precision integral frame closed single and double point press, 5. CNC precision closed multi-link press). Participated in the formulation of 5 industry standards of the Ministry of Machinery (1, closed multi-station press accuracy, 2, semi-closed fast press technical conditions, 3. semi-closed fast press accuracy, 4, closed multi-link cold and warm extrusion Presses, 5. Total of pneumatic rotary joints for mechanical presses), has been submitted for approval and awaiting release. Since 2015, more than 20 new products have been developed, and the company has 20 intellectual property rights, including 2 invention patents and 18 new utility patents.

4. Standardize fine management and create high-quality products. The company strictly follows ISO9001 (quality), ISO10012 (measurement), ISO24001 (environment), ISO28001 (occupational health and safety) system management documents, clarifies the main responsibilities, and earnestly implements the safety, environmental protection, quality responsibility system and "one post with two responsibilities, all Co-management and dereliction of duty" system; formulate safety and environmental risk emergency plans and other risk management systems, carry out emergency drills every year, and guide various departments and production sites to prevent and manage major quality, safety, and environmental accidents that may occur.

Strengthen the quality performance management of each responsible entity, strictly manage the quality process, organize and carry out QC (quality control) quality activities, enhance the awareness of quality improvement of all employees, and organize quality analysis meetings, related department quality exchange meetings, and special projects regularly or irregularly Issue review meetings and other measures to strictly control quality risks, realize full-staff quality awareness, standardize on-site management, and create "quality projects" with the "craftsman spirit" of excellence. Decompose and implement the annual plan, monthly plan, and weekly plan according to the planning goals, and use this as the control goal, focusing on procurement control, warehouse control, and workshop control, vigorously promote 6S on-site control, and insist on "practical" and "detailed" efforts , To promote the coordinated improvement of all departments and links of the company, consolidate the foundation, reduce costs and increase efficiency; strictly implement the assessment and reward system, firmly establish the idea of "strict management is love", pay attention to the early, prevent the slightest, and do not miss every detail And loopholes, there is always supervision, and everything is controlled. Established a product test center, equipped with high-precision laser detectors and other advanced equipment, to perform performance tests on products. The entire process from product development to finished products is strictly inspected and tested in accordance with the national forging machinery inspection standards to ensure the quality of product delivery. Satisfy customers needs.

5. Adhere to people-oriented and promote the implementation of human resource planning. The company has established a multi-channel and hierarchical talent training system to create opportunities for employees' learning and growth. Based on external attractiveness, maintaining the competitiveness of the talent market, and internally fair and consistent compensation strategy, an incentive compensation management system has been designed. Scientifically set job performance indicators, strictly implement performance appraisal, and comprehensively apply the appraisal results to salary adjustment, job promotion, job transfer, job matching, advanced appraisal, education and training, and implement positive incentives and positive elimination to attract, retain and encourage Excellent talents create an excellent team. Around the core values of "integrity, cooperation, innovation, responsibility", build three cultures, school culture (learning, growth), family culture (united, caring, considerate), and military culture (teamwork, execution, combat effectiveness), and build A distinctive, open and innovative corporate culture. Develop a variety of employee activities, organize employee tours in Huangshan and Xiamen, basketball games, corporate social gatherings, climbing Zhushan and barbecue, "Chongyang Nine-Nine" climbing and other activities. New employee training, senior fitter examination training, departmental business training And military training (Whampoa special training) and other series of training. The company cares about the lives of employees, guarantees employee benefits, employees enjoy "five insurances", free working meals, birthday benefits, holiday benefits, year-end red envelopes, start-up red envelopes and other benefits.

6. Focus on brand promotion and improve brand awareness. It owns the domestic registered trademark "640.webp (14).jpg", and invests more than 500,000 yuan each year to produce exquisite samples and brochures to enhance the corporate image. In addition to printing trademarks on products and packaging, the company vigorously uses registered trademarks in the design and production of samples and brochures, exhibition hall design of various exhibitions, and new product launches, which has continuously increased the visibility of the company's products in the market.

Actively participate in various large-scale trade fairs. Since its establishment, the company has actively organized and participated in various exhibitions and trade fairs every year, such as: domestic machine tool exhibitions such as Beijing International, Shanghai Pudong, Tianjin, Shenyang, Qingdao, and international machine tools such as Hanover, Russia, Turkey, Vietnam, and India. Through the exhibition, a large number of merchants have been made, and the products have been continuously sold throughout the country, and the international market has been continuously expanded, so that the brand influence of the company's products has been continuously improved.

Intensify the publicity of media advertisements. The company is willing to invest in advertising. In order to start the "640.webp (14).jpg" trademark, the company has increased the publicity of trademarks and enterprises, and has made great efforts in newspapers, professional magazines, and the Internet. Promote the company's image, leading products and trademarks, so that the visibility of the company and trademarks continues to expand.

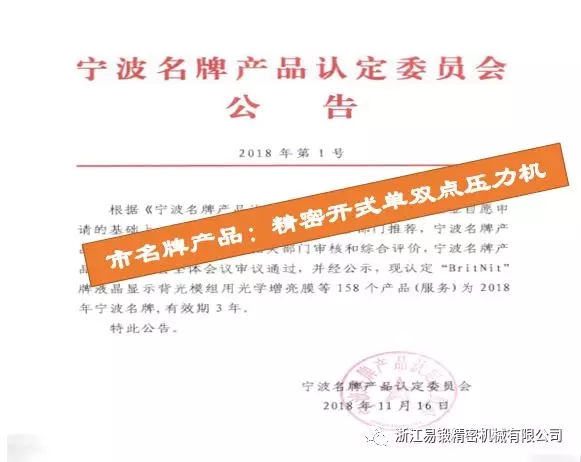

In 2018, one of the company's products, "Precision Open Single and Double Point Press", won the city's famous brand product, and strives to create high-quality products made in Zhejiang.

No matter how hard you work, you get nothing. In 2017, the company's sales revenue reached 164 million yuan, an increase of nearly 200% over 2016. In 2018, the estimated sales revenue is 260 million yuan, an increase of more than 50% over 2017. The company's transformation, upgrading and rapid development have won high recognition from government departments at all levels, all walks of life, and new and old customers. 2018 was even more fruitful.

The Xiangshan County Mayor’s Quality Award is the highest quality honor established by the Xiangshan County People’s Government. It is the county government’s contribution to the establishment and implementation of an excellent performance management model to promote the improvement of product quality, service quality, engineering quality, and environmental quality, and achieve significant economic benefits. The highest quality reward established by a socially beneficial enterprise or organization. The government organizes review once a year, and no more than 3 award-winning companies or organizations are awarded each year.

Since the evaluation of the Xiangshan County Mayor’s Quality Award in 2011, the Xiangshan County Market Supervision Bureau has attached great importance to the gradual cultivation of enterprises applying for the government’s quality awards, actively doing a good job in bridging quality management experts and enterprises, and guiding enterprises to introduce advanced quality management models. Continuously improve the quality management level of enterprises in our county. At present, 12 enterprises have been awarded the County Mayor Quality Award, namely:

the year 2011

▼

Ningbo Shenling Elevator Parts Co., Ltd.

the year of 2012

▼

Ningbo Dawei Medical Equipment Co., Ltd.

Ningbo Lawrence Automotive Interior Parts Co., Ltd.

the year of 2013

▼

Ningbo Tianan (Group) Co., Ltd.

Risheng Group Co., Ltd.

2014 year

▼

Zhejiang Qixin New Energy Technology Co., Ltd.

2015 year

▼

Ningbo Heli Mould Co., Ltd.

2016 year

▼

Ningbo Weilin Residential Facilities Co., Ltd.

2017 year

▼

Ningbo Rixing Casting Co., Ltd.

2018 year

▼

Ningbo Huazhong Plastic Products Co., Ltd.

Ningbo Jinlang New Energy Technology Co., Ltd.

Zhejiang Yiduan Precision Machinery Co., Ltd.

Evaluation site of Zhejiang Yiduan County Mayor Quality Award