How to choose a suitable high-speed punch press must be determined according to its own production rules, in addition to taking into account various parameters. Here, precision punch manufacturers for friends interpretation: high speed punch effective selection must be based on what parameters?

1、 According to the characteristics of the stamping process, the high-speed punch can produce large quantities of sizes, specifications and accuracy of stamping parts.

1. Open type mechanical punch is selected for the production of small and medium-sized parts with variable curvature.

2. In the production of medium-sized stamping parts, the mechanical high-speed punch with closed test structure is selected.

3. For small batch production, hydraulic press is selected for the production of large thick plate stamping parts.

4. High speed punch or multi process automatic punch press is used in mass production or in the production of complicated parts.

2、 The selection of high-speed punch press can be determined according to the specification and punching pressure of pressing die in stamping equipment department

1. The scale of the selected punch must exceed the total punching pressure required for stamping.

2. The stroke of the press should be moderate: the stroke immediately endangers the key height of the die, the lead is too large, the die seat is separated from the guide plate, the guide plate mold or the guide pillar guide sleeve is separated.

3. The closing height of the punch should be consistent with that of the die, that is, the closing height of the die is close to the middle of the larger closing height and the least closing height of the punch.

4. The size of the working table of the punch must exceed the size of the lower die seat of the die, and the space for installation and fixation should be reserved. However, the worktable should not be too large to prevent the poor bearing capacity of the worktable.

3、 The punch can also be determined according to the accuracy of the product to be punched:

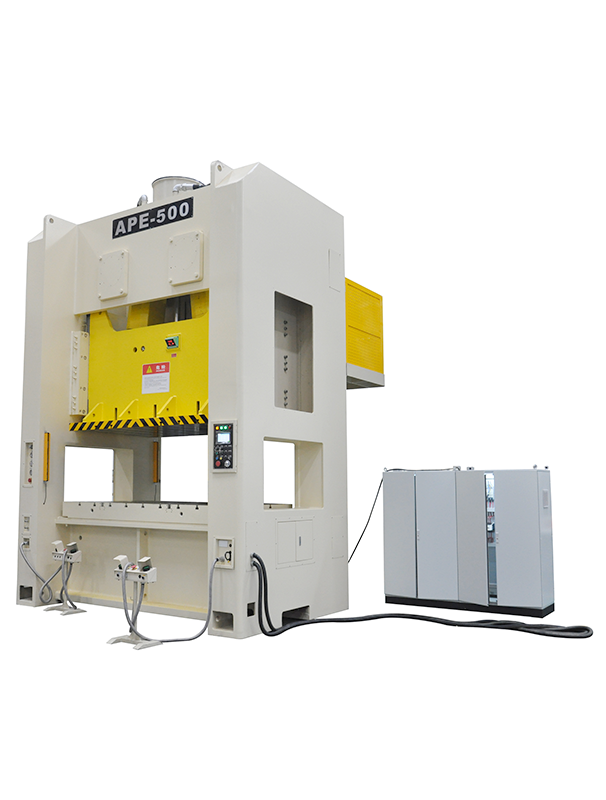

High speed punch has C-type punch and gantry punch. Because of its unique excellent production process, the production accuracy, stability and speed of gantry punch must be better than that of C-type punch. Therefore, if customers have particularly high requirements on stamping products, it is better to select gantry punch.