Tel:0574-59128998

Fax:0574-59128930

Mail:sales@nbyiduan.com

Add:Dalin village, Huangbiao Town, Xiangshan County, Ningbo, China

Web:www.nbyiduan.com

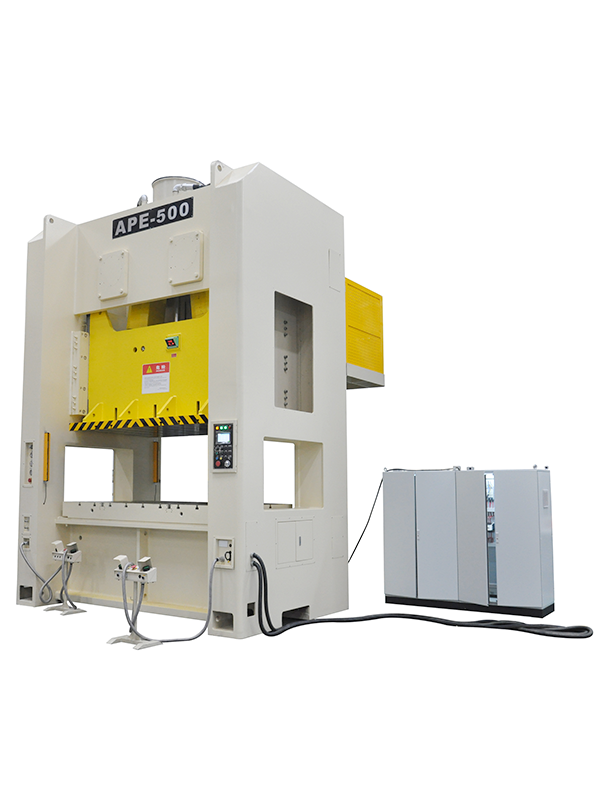

Precision punch manufacturers manufacturing presses can be generally divided into hot processing and cold processing two methods. Hot working is to study how to use casting, forging, welding, heat treatment, surface treatment and other methods to make materials into blank or directly process: blank or parts with certain performance, also known as material processing engineering.

Casting refers to melting metal, aluminum alloy or composite materials into liquid state and pouring them into the mold with certain shape and forming after solidification; forging refers to forming ingot, bar and plate through different forging machines at a certain temperature; welding refers to splicing several parts into complex integral parts or components through local melting or mutual diffusion. Heat treatment refers to the mechanical, physical and chemical properties of materials by changing the internal structure of parts by different heating and cooling methods. Heat treatment only changes the properties of the material and does not change the shape of the parts.

The surface treatment of parts is to change the composition or structure of parts surface to improve the performance of parts. The main purpose of cold working in mechanical manufacturing is to form blank or material into parts with high precision and low roughness area, and assemble the parts into machines. The use of precision punch makes the production capacity and efficiency of various processing methods improved unprecedentedly.

Expertise in researching and developing precision and high speed punching press machine!

pursue quality with dedicated service